30 Nov DAHON Patented DELTECH- the Gamechanger for Folding Bike Design

Triangular frames have long been considered the industry standard for bicycles, a design structure optimizing strength and stiffness with minimal extra weight. Single-beam folding bikes have been favored by the trade due to their cost-competitive, lightweight, and compact designs, however, there have been concerns about their safety and performance.

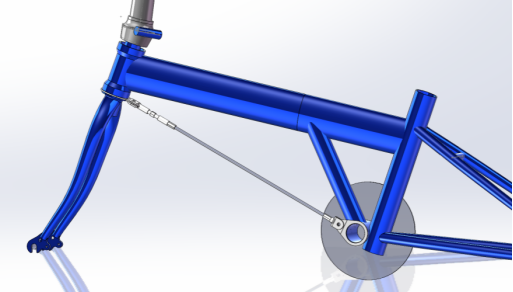

DAHON’s R&D team has perfected a nifty cable that upgrades single-beam folding bikes into a stronger triangular framed design. After DAHON’s success in the patent application, the design for such reinforced cable is named as “DELTECH”.

Already in use by many of DAHON’s single-beam folding models, DELTECH transforms the way the frame’s strength is carried. It takes on maximum weight from the frame to create a stable triangular structure and works perfectly in sync with bicycle wiring, without disturbing the folding process.

DAHON’s groundbreaking DELTECH cable:

- Greatly enhances the maximum load capacity of the bike

- Increases frame’s strength x10

- Adds 15% of longitudinal stiffness to overall bike rigidity

- Creates a more powerful pedaling force, helping riders to go faster* and save energy

The DELTECH is a great leap forward for the industry, massively elevating single-beam folding bikes with strength and stability to ride further.

The Birth of DELTECH Cable

Historically, bikes have used a triangular frame which is designed to optimize required strength and stiffness with minimal extra weight. This structure has always been considered the industry standard. There’s a wide variety of bicycles, as well as material and application developments in the market, but they rarely stray from this triangular frame structure.

With industry demand for more cost-competitive, lightweight and compact solutions, single-beam folding bikes have emerged. However, to an extent, the safety and performance of them have been compromised. Most single-beam folding bikes have a hinge centered in the frame between the front and rear wheels, which takes on the frame’s maximum force. The majority of folding hinges are woven into the main tubing using argon arc welding, however structural stress on welded joints is unavoidable, as well as occasionally flawed welding.

During riding, the folding parts bear 5-10 times the rider’s weight, resulting in bending forces. Under this continuous stress, the folding hinge loosens and stays loose, making annoying noises and its lifespan is greatly reduced. Over time, these phenomena are more or less compromising bicycle safety, fractures in folders aren’t big news anymore.

After years of rigorous research, DAHON supports that folding bicycles should re-adopt the standard triangular frame structure. The R&D team successfully developed a patented cable named as DELTECH to strengthen the folding frame with the downtube.

DELTECH Contributes to Frame Rigidity, Max Load, and Speed

DELTECH improves single-beam folding bicycle frames by forming a stable triangular structure, which becomes the stress point for the overall weight distribution. As a result, the impact on other folding parts becomes smaller without loosening the joints, while greatly improving the maximum load capacity for bike. It’s good news for riders with taller and heavier body built.

It also boosts the longitudinal rigidity of bicycles by 15%. During riding, the frame feels very strong and stable, and pedaling force effectively converts into propulsion, helping riders to save energy. The performance of bikes using DELTECH exceeds single beam models that don’t have it, as well as some road bikes & mountain bikes. DAHON did indoor testing and discovered that its 20-inch folding bikes equipped with DELTECH are: 5-10% faster than its folding bikes without it, 5% faster than mountain bikes, 7% faster than road bikes, and 36% faster than other folding bicycle brands.

The DELTECH cable is a great leap forward for the industry, it works perfectly in sync with bicycle wiring without disturbing the folding process. The groundbreaking DELTECH is a good example of DAHON’s legacy as a leading brand in bicycle technology.

DELTECH installation methods:

- The rear of the DELTECH is directly welded onto the frame. Advantages of this method include its low cost, simplistic structure, and can be mass produced by OEMs.

- B. Add-on: The front of the DELTECH is installed below the front tubing, and the rear is mounted on the bottom bracket headset. The advantage of this design is great news globally, as it can be installed on DAHON’s bikes not installed with DELTECH. It can also be mass produced by bike manufacturers, it’s a revolution for strengthening and modifying single-beam folding bike designs.

(Note: Tension of the DELTECH can be adjusted to 250N – 350N )

Whether equipped with DELETEC or not, DAHON folding bike is still recognized as one of the safest and most stable folding bikes in the world. With DELTECH, DAHON folding bikes are taken to the next level, offering more power, speed, and stability. This is our DELTECH, the gamechanger for folding bikes.

Further Reference of DELTECH Design by Dr David Hon, DAHON Founder & CEO: